Permanent Magnet Synchronous Medium Voltage Inverter Mixer Drive (PMS MV Inverter Mixer Drive) motors are known for their efficiency and high-power density. These motors use permanent magnets to generate the magnetic field, which reduces energy losses compared to traditional induction motors. This results in higher efficiency and lower operating costs. Medium Voltage Variable Frequency Drives (MV Inverter Drives) offer precise control over motor speed and torque.

When combined in mixer applications, these technologies create a powerful solution. Mixer drives are essential in industries where precise mixing is critical, such as chemical processing and food manufacturing. Fuji Electric provides a range of products, including Low Voltage Variable Frequency Drives (LV VFD), Medium Voltage Variable Frequency Drives (MV VFD), and motors, making them a key player in this field.

What Is a PMS MV Inverter Mixer Drive?

A PMS MV Inverter Mixer Drive is a high-performance drive system used to power medium-voltage motors in mixer applications. It consists of:

-

Uses permanent magnets instead of rotor windings

-

Offers high efficiency, high torque, and compact design

-

Ideal for heavy loads and low-speed operations common in mixers

-

Converts AC to DC and then to adjustable-frequency AC

-

Provides precise speed & torque control

-

Supports wide speed ranges and improved process stability

-

PLC + HMI integration for intuitive operation

-

Real-time monitoring with parameter adjustment

-

Automation for repeatable, high-quality mixing cycles

Where It’s Used

PMS MV Inverter Mixer Drives serve critical roles in:

Components of a PMS MV Inverter Mixer Drive System

A PMS MV Inverter Mixer Drive system consists of three key components: the PMS motor, the medium voltage inverter (VFD), and the control system.

PMS Motor

PMS motors offer several advantages, including high efficiency and power density. These features make them particularly suitable for mixer applications, where consistent performance is crucial. Their design ensures reliable operation, even in demanding environments.

PMS motors also provide high torque at low speeds, which is beneficial for mixers that need to handle thick or heavy materials. This capability ensures that the mixing process can be optimized for different types of materials.

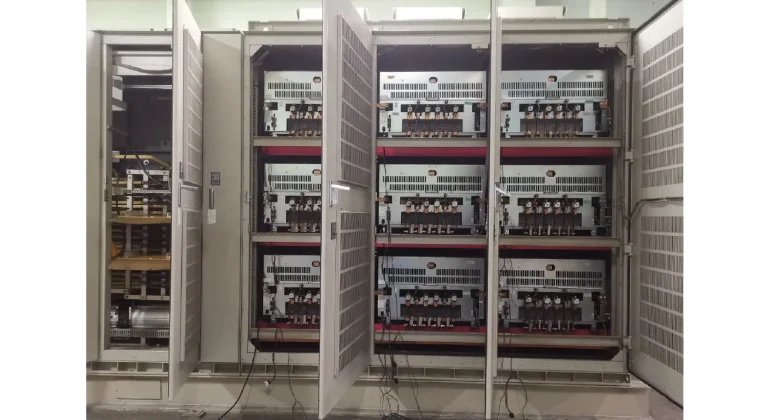

Medium Voltage Inverter (VFD)

The inverter stage converts DC voltage to AC voltage, allowing for precise speed control. MV drives typically use step-up transformers to increase voltage and multilevel inverters to create a sinusoidal output waveform. This setup is ideal for mixer applications, where torque control and a broad speed range are essential.

The ability to adjust speed and torque ensures that the mixing process can be optimized for different materials and recipes. This flexibility is particularly important in industries where product consistency is critical.

Control System

A Programmable Logic Controller (PLC) integrates seamlessly into the system. The Human Machine Interface (HMI) allows users to monitor and control the mixing process. This setup provides real-time data and allows for quick adjustments.

Operators can set specific parameters, such as speed and torque, to match the requirements of the material being mixed. This level of control ensures consistent product quality and reduces waste. Additionally, the control system can be programmed to automate certain processes, further improving efficiency.

Fuji Electric Solutions for Mixer Drives

Fuji Electric offers a range of MV VFDs suitable for mixer applications. While specific product models may vary, their technical specifications and benefits are designed to optimize performance. For instance, their MV VFDs often include advanced features like vector control and harmonic reduction, which improve motor efficiency and reduce electrical noise.

They provide matching PMS motors that ensure optimal performance. Fuji Electric’s components integrate to form a complete mixer drive solution, making it easier for industries to implement these systems.

Pro-Tip:

When selecting a VFD, always check its compatibility with your existing motor and power supply. This ensures smooth integration and optimal performance. Additionally, consider the scalability of the system to accommodate future upgrades or changes in production requirements. Scalability is important for industries that anticipate growth or changes in their operations.

Fuji Electric Sales Phils. Inc.

Advantages of Using PMS MV Inverter Mixer Drives

PMS MV Inverter Mixer Drives offer many advantages:

Energy Efficiency

These systems consume less power. This translates to lower operating costs and reduced environmental impact. Energy efficiency is particularly important in industries where energy costs are high.

Improved Process Control

Operators achieve precise control over mixing parameters, leading to better product quality and consistency. This control ensures that products meet the required standards, reducing the need for rework or waste.

Reduced Maintenance

Robust designs reduce downtime and maintenance needs. This means less time spent on repairs and more time on production. Reduced maintenance also leads to lower maintenance costs over time.

Increased Reliability

These systems operate reliably, even in demanding industrial environments. This reliability ensures that production schedules are met without interruptions. Reliability is crucial for maintaining customer satisfaction and meeting delivery deadlines.

Cost Savings

Long-term, the benefits add up to significant cost savings. Reduced energy consumption and lower maintenance costs contribute to a better bottom line. These savings can be reinvested in other areas of the business, such as research and development or expansion

Applications

Industries like chemicals, wastewater treatment, and food and beverage benefit from PMS MV Inverter Mixer Drives. These drives are useful in many specific mixer applications. For instance, in chemical processing, precise mixing is crucial for creating consistent products.

In wastewater treatment, mixers are used to blend chemicals for water purification, where precise control is essential for effective treatment. In the food industry, mixers are used for blending ingredients, where consistency and quality are paramount.

Frequently Asked Questions

What is the purpose of the inverter stage in a VFD?

The inverter stage converts the DC voltage into a variable-frequency AC voltage to control the motor’s speed. This allows for precise control over the motor, which is essential for applications requiring variable speed.

How does a medium voltage drive work?

MV drives use a step-up transformer to increase voltage and a multi-level inverter to create a sinusoidal output. This process ensures that the drive can handle higher voltage levels while maintaining efficiency.

What is a speed drive inverter?

It controls the speed of an AC motor by varying the frequency and voltage. This is crucial for applications that require adjustable speed, such as mixers.

What is the difference between VFD and inverter drive?

VFD is the complete system, while the inverter is a key component within it. The inverter does the DC-to-AC conversion, but the VFD includes additional components like the control system.

Is VFD good or bad?

VFDs are generally “good” for energy savings and control, but proper installation is crucial. Improper setup can lead to inefficiencies or even damage to the system.

Pro-Tip:

Regularly monitor your VFD’s performance metrics, such as voltage, current, and temperature. Early detection of anomalies can prevent costly breakdowns. This proactive approach ensures your system runs smoothly and efficiently.

Fuji Electric Sales Phils. Inc.

Regular monitoring also helps in identifying areas for improvement, allowing for continuous optimization of the mixing process.

PMS MV Inverter Mixer Drives boost efficiency, improve control, and reduce costs in mixing applications. Fuji Electric’s solutions stand out in this area. They offer reliable and integrated systems. Consider contacting Fuji Electric for more details on how these solutions can benefit your operations. By understanding and leveraging these technologies, industries can optimize their mixing processes, leading to better products and reduced operational costs.

Whether you’re in chemical processing, food manufacturing, or another industry, PMS MV Inverter Mixer Drives can help you achieve your production goals more effectively. This technology not only enhances current operations but also positions businesses for future growth and competitiveness.