Definition, Types and Applications of Electric Motors

Electric motors are essential devices that convert electrical energy into mechanical motion, making them a fundamental component of modern technology and industry. From everyday household appliances to large-scale industrial machinery, electric motors play a critical role in powering equipment across a wide range of applications. This guide provides a clear overview of electric motors, including their definition, working principle, common types, and practical applications. By understanding these fundamentals, readers can make informed decisions when selecting, using, and maintaining electric motors for various operational needs.

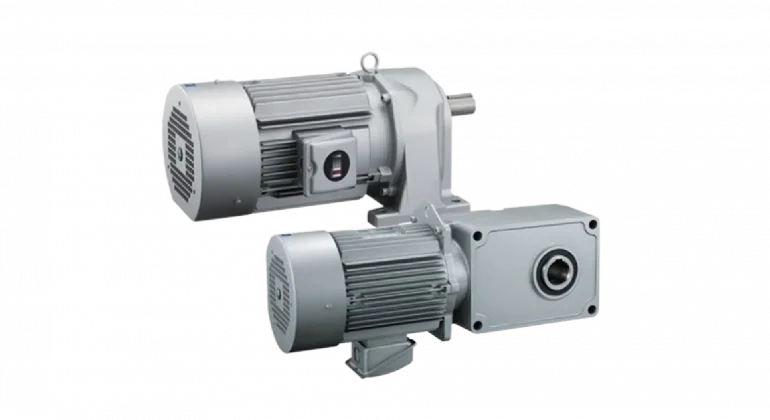

Types of Electric Motors

Electric motors are not designed as a single universal solution, as different applications require different performance characteristics. Electric motors are classified into various types based on factors such as power supply, operating principle, speed control, efficiency, and intended application. From simple designs used in household appliances to more advanced motors found in industrial and commercial systems, each type of electric motor is engineered to meet specific operational needs. Understanding these motor types helps users select the most suitable motor for a given application, ensuring reliable performance, energy efficiency, and long-term operation.

AC Motors

AC motors are electric motors that operate using alternating current (AC) power and are among the most widely used motor types in industrial and commercial applications. Known for their durability, efficiency, and relatively simple construction, AC motors are commonly used in equipment such as pumps, fans, compressors, conveyors, and production machinery. They are available in different designs, including induction motors and synchronous motors, each suited for specific speed, torque, and control requirements.

Induction Motors

Induction motors are one of the most commonly used types of AC motors due to their simple design, reliability, and low maintenance requirements. Unlike some other motor types, induction motors do not use brushes or commutators, which reduces mechanical wear and minimizes servicing needs. These motors operate by inducing current in the rotor through a magnetic field, allowing them to run efficiently at a nearly constant speed. Induction motors are widely used in applications such as fans, pumps, blowers, compressors, and conveyors, where continuous operation and durability are more important than high starting torque or precise speed control.

Synchronous Motors

Synchronous motors are a type of AC motor that operates at a constant speed, synchronized with the frequency of the power supply. This precise speed control makes them ideal for applications where timing and accuracy are critical. Unlike induction motors, synchronous motors maintain a fixed speed regardless of the load, providing reliable performance in processes that require exact coordination. They are commonly used in clocks, robotics, conveyor systems, precision machinery, and other industrial applications where consistent rotation and timing are essential. Additionally, synchronous motors are highly efficient and can be used for power factor correction in electrical systems, making them valuable in both industrial and commercial settings.

DC Motors

DC motors are electric motors that operate using direct current (DC) power and are well known for their ability to provide precise speed and torque control. Because of this capability, DC motors are commonly used in applications where adjustable speed and smooth performance are required, such as conveyors, electric vehicles, robotics, and control systems. Their simple speed control characteristics make DC motors suitable for both industrial and specialized applications.

Brushed DC Motors

Brushed DC motors are one of the traditional types of electric motors, using brushes and a commutator to deliver current to the motor windings. This design allows for straightforward control of speed and torque by simply adjusting the voltage, making brushed DC motors simple, cost-effective, and easy to operate. However, because they rely on physical brushes, they are prone to wear and require periodic maintenance to ensure long-term operation. These motors are commonly found in applications such as household appliances, power tools, toys, and small machinery, where their simplicity and low initial cost outweigh the need for high durability or continuous operation.

Brushless DC Motors

Brushless DC motors, often abbreviated as BLDC motors, are an advanced type of DC motor that do not use brushes or a commutator. Instead, they rely on electronic controllers to deliver current to the motor windings, which reduces mechanical wear and improves efficiency. Because of this design, BLDC motors have a longer lifespan, require less maintenance, and offer higher performance than traditional brushed DC motors. These motors are widely used in high-performance and precision applications, including drones, electric vehicles, robotics, computer cooling fans, and industrial automation systems, where efficiency, reliability, and precise control are essential.

Servo Motors

Servo motors provide precise control of position, speed, and acceleration, thanks to an integrated feedback system that monitors and adjusts motion in real time. These motors are commonly used in robotics, automation, CNC machines, and other high-precision applications where accuracy and repeatability are essential. Their precise control capabilities make them indispensable in industries like manufacturing, aerospace, and medical technology.

Fuji Electric’s Motor Offerings

Fuji Electric provides a wide range of high-quality electric motors designed to meet diverse industrial and commercial needs. Their offerings include AC motors, DC motors, induction motors, synchronous motors, brushless DC motors, and servo motors, each engineered for specific performance requirements. These motors are built for reliability, efficiency, and long-term operation, making them suitable for applications such as manufacturing, automation, HVAC systems, robotics, and energy management. Fuji Electric also provides detailed specifications, performance data, and application guidance on their website, helping engineers and businesses select the most suitable motor for their unique operational requirements.

Components of an Electric Motor

- Stator

- Rotor

- Windings

- Commutator

- Bearings

How Electric Motors Work (Principles of Operation)

Electric motors operate based on fundamental principles of electromagnetism, which describe how electric currents interact with magnetic fields to produce motion. When an electric current flows through a conductor within a magnetic field, it generates a force that causes mechanical movement. Electric motors are designed to harness this interaction in a controlled manner, allowing electrical energy to be converted efficiently into mechanical motion. Understanding these basic operating principles provides a foundation for learning how different types of electric motors function and why they are used in various applications.

Electromagnetic Induction

Electromagnetic induction occurs when a changing magnetic field creates an electric current in a conductor. This principle is essential to AC motors, where the constantly changing magnetic field induces current in the rotor, generating motion without direct electrical contact. It is a core concept in converting electrical energy into mechanical energy.

Lorentz Force

The Lorentz force is the fundamental force that causes a motor’s rotor to spin. It occurs when a charged particle, such as an electron in a current-carrying conductor, moves through a magnetic field, generating a perpendicular force. In both AC and DC motors, this force acts on the conductors in the rotor, producing rotational motion. The direction and magnitude of the force depend on the current flow and the orientation of the magnetic field, which is why motors are carefully designed to control these factors. Understanding Lorentz force is key to grasping how electrical energy is converted into mechanical motion in electric motors.

AC Motor Operation

AC motors use alternating current to produce a rotating magnetic field in the stator. This field induces current in the rotor, generating torque and rotation. The smooth, continuous motion of AC motors makes them suitable for constant-speed applications like fans, pumps, and conveyor belts, with different AC motor types offering specialized performance characteristics.

DC Motor Operation

DC motors operate using direct current (DC) to generate a magnetic field in the stator or rotor. A key component, the commutator, periodically reverses the direction of current in the rotor windings, ensuring the rotor continues spinning in a single, consistent direction. This controlled current flow allows DC motors to provide precise speed and torque control, making them ideal for applications such as electric vehicles, conveyor systems, robotics, and small machinery. By adjusting the voltage or current, operators can easily regulate motor speed, giving DC motors a level of flexibility that is particularly useful for variable-speed applications.

Applications of Electric Motors

- Industrial Applications

- Commercial Applications

- Automotive Applications

- Other Applications

Motor Control and Drives

Motor control systems are used to manage and regulate the speed, torque, and direction of electric motors, ensuring optimal performance for different applications. A key component in these systems is the Variable Speed Drive (VSD), which allows motors to operate at adjustable speeds rather than a fixed rate. VSDs improve energy efficiency, reduce mechanical stress on motor components, and provide precise control over motor operation. Motor control systems are widely used in industrial automation, HVAC systems, pumps, conveyors, and robotics, where varying speed and torque are required to match process demands.

- Low Voltage Variable Frequency Drives VFDs (LV VFD)

- Medium Voltage Variable Frequency Drives VFDs (MV VFD)

Importance of Motor Control

Motor control plays a critical role in ensuring electric motors operate efficiently, reliably, and safely. By regulating speed, torque, and direction, motor control systems help reduce energy consumption, minimize mechanical stress, and extend motor lifespan. Precise speed and torque adjustment is especially important in industrial processes such as conveyor systems, pumps, compressors, and automated machinery, where exact performance is required to maintain product quality and operational efficiency. Additionally, effective motor control can reduce maintenance costs, prevent equipment downtime, and optimize overall energy use, making it a key factor in sustainable and cost-effective operations.

Maintenance and Troubleshooting

Electric motors require regular maintenance to ensure consistent performance and long service life. Routine checks and timely troubleshooting help prevent breakdowns, improve efficiency, and reduce the risk of unexpected downtime. Understanding basic maintenance practices also makes it easier to identify and resolve common motor issues before they become serious problems.

Common Problems

Electric motors can experience several common issues during operation, especially when maintenance is insufficient or operating conditions are not ideal. Overheating is often caused by excessive load, poor ventilation, or electrical imbalances, while bearing failure can result from improper lubrication, misalignment, or contamination. Winding insulation breakdown may occur due to prolonged heat exposure, electrical stress, or aging materials, and commutator wear is typically associated with brushed motor designs and normal mechanical friction. If these problems are not identified and addressed promptly, they can lead to reduced performance, unplanned downtime, or complete motor failure.

Preventative Maintenance

Preventive maintenance plays a crucial role in extending the service life and maintaining the efficiency of electric motors. Regular cleaning, proper lubrication, and routine inspections help prevent many common motor problems before they occur. Keeping motors clean reduces dust and debris buildup, which can restrict airflow and lead to overheating. Lubricating bearings and moving parts minimizes friction and wear, while periodic inspections allow early detection of issues such as loose connections, abnormal vibrations, or unusual noise. Implementing a consistent preventive maintenance schedule helps ensure reliable motor operation and reduces the risk of unexpected failures.

Basic Troubleshooting

Basic troubleshooting helps identify common electric motor issues before they lead to serious damage or failure. Checking for loose electrical connections, damaged or worn wiring, and signs of overheating can reveal electrical problems that affect motor performance. Unusual noises, vibrations, or changes in operating sound often indicate mechanical issues such as bearing wear, misalignment, or imbalance. Observing these warning signs early and addressing them promptly can help prevent further damage, reduce downtime, and maintain safe motor operation.

Pro-Tip:

A good multimeter is an essential tool for basic electric motor troubleshooting. It helps measure voltage, current, and resistance, making it easier to identify electrical issues such as loose connections or abnormal readings. Regular use of a multimeter allows early detection of problems, helping prevent unexpected motor failures and costly repairs.

Fuji Electric Sales Phils. Inc.

Fuji Electric Products and Solutions

Fuji Electric offers a comprehensive portfolio of products and solutions that support the efficient operation, control, and optimization of electric motor systems. Beyond electric motors themselves, these products are designed to enhance performance, improve energy efficiency, and ensure reliable operation across a wide range of industrial and commercial applications. By integrating motors with advanced control, protection, and monitoring technologies, Fuji Electric provides end-to-end solutions tailored to diverse operational requirements.

Industrial Components

- Motors

- Low Voltage Variable Frequency Drives (LV VFD)

- Medium Voltage Variable Frequency Drives (MV VFD)

- Servo Systems

- Programmable logic controller — PLC

- Human machine interface — HMI

Fuji Electric’s offerings are designed to address a wide range of industrial requirements, supporting efficient and reliable electric motor operation across different sectors. By focusing on performance optimization, energy efficiency, and system reliability, these products help improve overall operational stability in applications such as manufacturing, automation, energy management, and infrastructure. This comprehensive approach enables industries to achieve consistent performance while meeting demanding operational standards.

Pro-Tip:

Keeping a maintenance logbook helps track the condition and performance of electric motors over time. By recording maintenance dates, tasks completed, and any issues found, users can identify trends and plan timely maintenance. This simple practice supports longer motor life and helps prevent unexpected downtime.

Fuji Electric Sales Phils. Inc.

Frequently Asked Questions

Is it worth repairing an electric motor?

It depends. Consider the cost of repair versus replacement. Also, factor in the motor’s size, age, and how critical it is to your operation. If the motor is old or the repair cost is high, replacing it might be more cost-effective.

How many years does an electric motor last?

A well-maintained electric motor can last 10-20 years or more. Load, environment, and maintenance all play a role. Regular upkeep can significantly extend a motor’s lifespan.

What goes bad in an electric motor?

Bearings, windings, insulation, and commutators (in brushed motors) are common failure points. These components are prone to wear and tear over time.

How do you make an electric motor more powerful?

You can increase the voltage or current (within safe limits). Also, stronger magnets, better cooling, and optimized design can help. However, always ensure these modifications are done safely and within the motor’s specifications.

Which is better AC or DC motor?

It depends on the application. AC motors are generally more efficient and reliable for constant-speed applications. DC motors offer better speed control, making them ideal for applications requiring variable speed.

Conclusion

Electric motors are essential to modern life. Understanding their types, components, and maintenance helps us keep things running smoothly. Whether it’s a tiny motor in a toothbrush or a massive motor in a factory, these devices quietly power our world. By staying informed and taking care of these essential machines, we can ensure they keep working for years to come. With the right knowledge and tools, you can optimize your motor’s performance and extend its lifespan.