About the Company

This company is a leading player in the food and beverage industry. It is known for producing high-quality condiments, sauces, and other food products, with steam filters as one of their tools for the operation. The business continually improves production methods to make them more effective, consistent, and cost-effective. Its dedication to delivering flavorful and safe products has made it a trusted name in households and businesses.

The Challenge

One critical challenge the company faced was the frequent breakage of its steam filter, a vital component in its food processing operations. The steam line plays a crucial role in the cooking process, and without proper monitoring, unexpected filter failures lead to production delays, inefficiencies, and increased maintenance costs. The absence of an advanced monitoring system made it difficult for the company to identify potential failures in advance, resulting in higher operational risks and unplanned downtime.

Before implementing Fuji Electric’s solution, this company faced a critical issue with the breakage of its steam filter. This problem directly affected its steam line, which is an essential component in the cooking process of its products. The company could not proactively prevent filter failures without an effective monitoring system, leading to operational disruptions.

Customer Requirements and Decision Process

They needed a reliable system that accurately monitors differential pressure in its steam line. This would help mitigate the issue by proactively detecting pressure fluctuations and potential filter failures before they disrupt operations.

When considering solutions, the company prioritized accuracy, durability, and seamless integration with its existing systems. It ultimately chose Fuji Electric based on the strong recommendation of its designated Instrumentation contractor, who recognized the superior performance of Fuji Electric’s products.

Key stakeholders, including the Project Engineer and the Instrumentation Contractor, made the final decision after evaluating the proposed solution’s technical capabilities and long-term benefits.

To address this issue, they required a monitoring system to measure differential pressure in the steam line. This would help them detect potential problems before they result in filter breakages.

When evaluating solutions, the company chose Fuji Electric based on the endorsement of their designated Instrumentation contractor. The decision-making process involved key stakeholders, including the Project Engineer and the Instrumentation Contractor.

The Solution

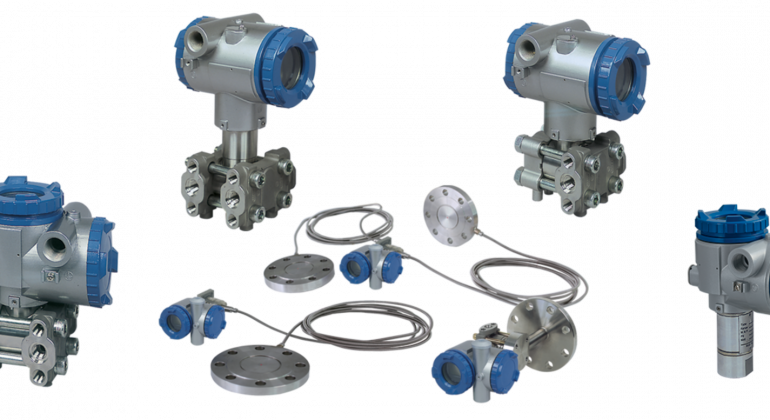

Fuji Electric provided the Differential Pressure Transmitter FCX-AIV Type FKC to address their needs. This state-of-the-art device continuously monitors the differential pressure within the steam line, allowing the company to detect potential issues in real-time. The transmitter’s precise measurements and robust design ensure long-term reliability, helping the company maintain stable production conditions and reduce equipment failures.

Fuji Electric provided them with the Differential Pressure Transmitter FCX-AIV Type FKC. This advanced instrument continuously monitors the steam line’s pressure, allowing the company to take proactive maintenance actions and prevent filter damage.

Implementation Process

The implementation process was carefully planned to ensure that it went smoothly and did not cause significant problems with production. The engineers under the company and Fuji Electric worked closely to ensure that the differential pressure transmitter was installed and worked properly.

Despite initial challenges aligning the new system with existing infrastructure, the combined expertise of both teams ensured a seamless setup. Regular performance tests validated the system’s accuracy and efficiency, giving the food and beverage company confidence in its upgraded monitoring capabilities.

The installation and integration process ensured minimal disruption to their operations. Fuji Electric’s PH technical team efficiently managed any challenges encountered during the installation, working closely with their engineers to ensure seamless integration.

Results and Impact

Following the integration of Fuji Electric’s Differential Pressure Transmitter, they experienced several key benefits that have significantly improved their operations:

-

- The differential pressure is tracked in real-time, which allows problems to be found quickly and lowers the chance that the steam filter will break.

-

- Enhanced process efficiency, leading to smoother production cycles and minimizing downtime.

-

- Cost savings on maintenance and replacements, as proactive issue detection prevents expensive repairs and unscheduled shutdowns.

-

- Increased equipment lifespan, reducing the frequency of steam filter failures and extending the durability of related components.

-

- Improved product consistency and quality, ensuring the cooking process remains stable, which translates to better quality control and product output.

The equipment has met and exceeded expectations, demonstrating outstanding reliability and performance in its production environment.

After implementing the Fuji Electric Differential Pressure Transmitter, they experienced significant operational improvements, including:

-

- Real-time monitoring of differential pressure, reducing the risk of steam filter breakage.

-

- Enhanced process efficiency, leading to fewer disruptions in production.

-

- Cost savings on maintenance and replacements due to early issue detection.

-

- Increased equipment lifespan, reducing the frequency of repairs and replacements.

-

- Improved product consistency and quality, ensuring that their cooking process remains stable and efficient.

The equipment has performed well, and the company is satisfied with its reliability and effectiveness.

Why Choose Fuji Electric?

Fuji Electric is dedicated to delivering cutting-edge industrial solutions designed to optimize efficiency, ensure safety, and reduce operational costs. The Differential Pressure Transmitter FCX-AIV Type: FKC exemplifies Fuji Electric’s commitment to precision engineering and innovation. Businesses across industries trust Fuji Electric for its:

-

- Advanced technology for precise and accurate measurements

-

- Seamless integration with various industrial systems

-

- Robust, high-quality design ensuring long-term durability

-

- Reliable technical support and customer service, ensuring smooth operations

With a proven track record in industrial instrumentation, Fuji Electric continues to be a trusted partner for companies seeking high-performance monitoring solutions.

Fuji Electric is committed to delivering high-quality industrial solutions that enhance operational efficiency, safety, and cost-effectiveness. Our Differential Pressure Transmitter FCX-AIV Type: FKC is a testament to our precision, durability, and reliability dedication. Key benefits of our instrumentation solutions include:

-

- Advanced technology for accurate measurement

-

- Seamless integration with existing systems

-

- Robust design for long-term reliability

-

- Expert technical support and customer service

Customer Endorsement

Their experience with Fuji Electric has been positive. Based on the high performance and reliability of the installed equipment, the company would recommend Fuji Electric solutions.

Conclusion

Integrating Fuji Electric’s Differential Pressure Transmitter helped it overcome its steam filter breakage issues. Thus, its operations have significantly improved efficiency, reliability, and cost-effectiveness. This case study underscores the value of proactive monitoring solutions in minimizing disruptions and enhancing food and beverage industry productivity.

With Fuji Electric’s expertise and advanced technology, companies can achieve excellent operational stability and maintain the highest production standards. Their experience is a testament to the power of precision instrumentation in driving industrial success.

Implementing Fuji Electric’s Differential Pressure Transmitter successfully helped them resolve their steam filter breakage issue. Furthermore, the study highlights how proactive monitoring solutions can significantly enhance operational efficiency and prevent costly disruptions in the food and beverage industry.

About Fuji Electric Sales Philippines, Inc.

Fuji Electric Sales Philippines, Inc. is committed to bringing reliable solutions from Japan’s Fuji Electric Co., Ltd. to the country. The company handles sales, promotion, and support of products that drive energy efficiency, support automation, and strengthen the electrical infrastructure.