Ultrasonic flowmeters are sophisticated instruments used to measure the flow rate of fluids within pipes. They operate on a counterintuitive principle: sound.

How Do Ultrasonic Flowmeters Work?

Consider sound waves moving through a flowing fluid. These waves, particularly ultrasound, are transmitted and received by transducers mounted on the pipe. The flow velocity of the fluid affects the travel time of these sound waves. By precisely measuring the difference in travel time between sound waves traveling upstream and downstream, the flowmeter can accurately calculate the fluid’s velocity and, as a result, its flow rate.

The fundamental principle of any flow meter is to measure the rate at which fluid flows through a specific cross-section. This can be achieved through various methods, such as determining the volume of fluid passing a point within a given timeframe, measuring the fluid’s velocity, or measuring the mass of fluid passing a point within a given timeframe.

What Type of Waves Are Transmitted?

Ultrasonic flowmeters utilize high-frequency sound waves, typically in the range of 20 kHz to 10 MHz, which are inaudible to the human ear. These waves can be transmitted through the pipe wall or directly into the fluid, depending on the specific flowmeter design.

Operating Principles of Ultrasonic Flowmeters

Transit-Time Principle

Ultrasonic flowmeters utilizing the transit-time principle measure the difference in travel time of ultrasonic pulses traveling in opposite directions through the flowing fluid. Two transducers are mounted on opposite sides of the pipe. One transducer transmits a pulse, which travels through the fluid to the other transducer. The time taken for this downstream travel is recorded. The process is then reversed, and the upstream travel time is measured. The difference in these travel times is directly proportional to the fluid velocity.

Doppler Principle

The Doppler principle in ultrasonic flowmeters relies on the frequency shift of an ultrasonic beam reflected by particles or bubbles moving with the fluid. An ultrasonic beam is transmitted into the flowing fluid and reflected by particles or bubbles carried along by the fluid’s movement. Due to the Doppler effect, the reflected beam exhibits a slight frequency shift. This frequency shift is directly proportional to the fluid velocity, allowing for accurate flow measurement.

Vortex Shedding Method

While not strictly ultrasonic, this method is often discussed in flow measurement discussions. It utilizes the vortices generated by an obstruction in the flow path to determine flow rate.

What are the different types of ultrasonic flowmeters?

-

- Clamp-on Flowmeters: These non-intrusive devices are easily installed on existing pipes without requiring any process interruption.

-

- Insertion Flowmeters: These flowmeters are inserted into the pipe, allowing for more accurate measurements in certain applications.

-

- In-line Flowmeters: These flowmeters are integrated directly into the pipeline, providing high accuracy but requiring more significant installation effort.

How accurate is the ultrasonic flowmeter?

The accuracy of an ultrasonic flowmeter depends on various factors, including the specific method used, the flow conditions, and the quality of the installation. Generally, these devices can achieve measurement accuracies within 0.5% to 2% of the actual flow rate.

Ultrasonic Detection Range

The maximum distance at which ultrasound can detect objects varies depending on several factors. Higher frequency sound waves are generally absorbed more quickly. The properties of the medium, such as density and temperature, as well as the presence of obstacles, can significantly influence sound wave propagation. Additionally, the power of the transmitter plays a crucial role. In practical applications, ultrasonic sensors typically have a detection range from a few centimeters to several meters.

What is the best way to measure flow rate?

The “best” way to measure flow rate depends entirely on the specific application and the characteristics of the fluid. Factors to consider include:

-

- Fluid properties: Viscosity, density, temperature, conductivity, and the presence of solids or gas bubbles.

-

- Pipe size and material: The diameter and material of the pipe will influence the choice of flowmeter and installation method.

-

- Flow rate range: The expected range of flow rates will determine the required measurement accuracy and the suitability of different flowmeter technologies.

-

- Installation constraints: Factors such as space limitations, access to the pipe, and the need for minimal process disruption will influence the installation options.

Pro-Tip: Ultrasonic flowmeters require the pipe to be completely full of fluid for accurate measurements. If there is a risk of partial filling, it is essential to install the meter in a location where full pipe flow is guaranteed. This can be particularly important in applications where fluid levels fluctuate.

Choosing the Right Ultrasonic Flowmeter

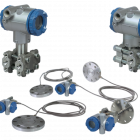

Selecting the most appropriate ultrasonic flowmeter for a particular application requires careful consideration of these factors. Fuji Electric offers a diverse range of high-quality flowmeters, including clamp-on, insertion, and in-line models, to meet the specific needs of various industries. Here’s an overview of the key types available:

Electromagnetic Flowmeter

Electromagnetic flowmeters are designed for measuring the flow of conductive liquids. They operate based on Faraday’s law of electromagnetic induction, where a voltage is induced in a conductor moving through a magnetic field. These flowmeters are widely used in industries such as water management, food processing, and chemical manufacturing. Fuji Electric provides two configurations:

-

- Integrated Type: Combines the sensor and converter in one unit, ideal for environments with favorable conditions. This comes in wafer or flange type.

-

- Separated Type: Features a remote sensor and converter setup, suitable for harsher environments and higher temperature applications, with the ability to withstand temperatures up to 150°C. This comes in flow transmitter, wafer, or flange type.

Ultrasonic Flowmeter

Ultrasonic flowmeters utilize ultrasonic waves to measure fluid flow. They are non-intrusive and can be categorized based on the medium they measure:

-

- Ultrasonic Type for Liquid: Available in portable (FSC), stationary (such as the M-Flow PW and TIME DELTA-C), and spool types (FST). These meters can accurately measure liquid flow rates without obstructing the flow path.

-

- Ultrasonic Type for Steam (FSJ): Specifically designed to handle steam applications, ensuring precise measurements even under varying temperature and pressure conditions.

-

- Ultrasonic Type for Air (FWD): Designed for air measurement in pipes ranging from 25 mm to 200 mm in diameter, these meters provide non-contact measurements and are battery-powered or operate on 24 V DC.

Compact Ultrasonic Flowmeter (S-FLOW)

The S-FLOW model is a compact ultrasonic flowmeter that stands out due to its space-saving design (116 x 42 x 43 mm). It is easy to install without requiring grease or complex adjustments. The S-FLOW is equipped with sensors suitable for various pipe diameters and allows for quick setup, making it an excellent choice for systems with limited space.

Key Features of S-FLOW

-

- Compact Design: Facilitates integration into existing systems.

-

- Easy Attachment: Simple installation process by screwing into place.

-

- No Delivery Timing Adjustment Needed: Ready for immediate use upon installation.

These flowmeters from Fuji Electric cater to a wide range of industrial needs, ensuring accurate and reliable measurements across different applications. Whether it’s for liquids, steam, or air, Fuji Electric’s innovative designs help optimize operational efficiency while maintaining high standards of accuracy.

Calibration of Ultrasonic Flow Meters

Ultrasonic flowmeters typically require periodic calibration to ensure the accuracy of their measurements. This process involves comparing the flowmeter’s readings to a known standard or a traceable reference.

Pro Tip: When calibrating ultrasonic flowmeters, it is crucial to ensure that the flow rate remains steady during the calibration process. Fluctuations in flow can lead to inaccurate measurements. To achieve this, set the flow to a specific rate and maintain it consistently throughout the calibration. For high-usage flowmeters, consider calibrating more frequently than the standard recommendation of once a year to maintain optimal accuracy and performance.

FAQs

Can ultrasonic flowmeters be used on all fluids?

While versatile, ultrasonic flowmeters may not be suitable for all fluids. Fluids with high gas content or significant suspended solids can interfere with sound wave transmission, impacting accuracy. High-viscosity fluids can also dampen sound waves.

How do I choose the correct mounting location for an ultrasonic flowmeter?

Proper mounting is crucial for accurate measurements. Ensure sufficient straight pipe runs upstream and downstream of the flowmeter to stabilize flow. Avoid mounting near valves, elbows, or other flow disturbances. For clamp-on sensors, ensure proper contact with the pipe surface.

Can ultrasonic flowmeters measure the flow of liquids and gases?

Yes, ultrasonic flowmeters can measure the flow of both liquids and gases, though the specific type and operating principle may vary depending on the fluid medium.

How do I maintain an ultrasonic flowmeter?

Regular maintenance is essential for optimal performance and longevity. Keep the flowmeter clean and free from debris. Inspect transducers and cables for damage. Check for leaks or wear and tear. Follow the manufacturer’s recommended maintenance schedule.

What are the advantages of using ultrasonic flowmeters?

Ultrasonic flowmeters offer several advantages. Clamp-on models are non-intrusive, requiring no process interruption. They can achieve high accuracy and are suitable for a wide range of fluids and flow rates. They typically require minimal maintenance and are used in various industries, including water and wastewater treatment, oil and gas, and chemical processing.

About Fuji Electric Sales Philippines, Inc.

Fuji Electric Sales Philippines, Inc. plays a key role in connecting the Philippines to the innovations of Fuji Electric Co., Ltd. from Japan. Through its local team, the company provides product sales, promotion, and support for technologies that enhance energy efficiency, automation, and electrical systems.

Let Fuji Electric’s ultrasonic flowmeter solutions enable you to achieve optimal performance. Should you have questions, please don’t hesitate to contact:

Rickson Manalo

Assistant Sales Manager

0917-115 6102